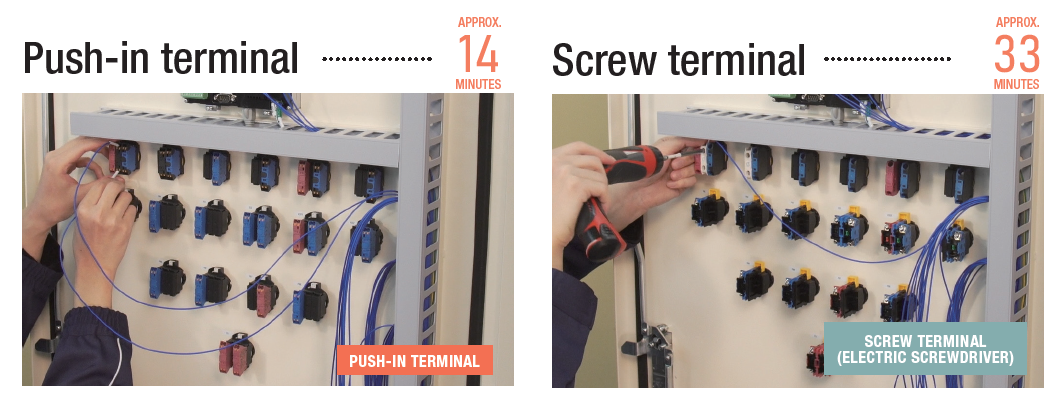

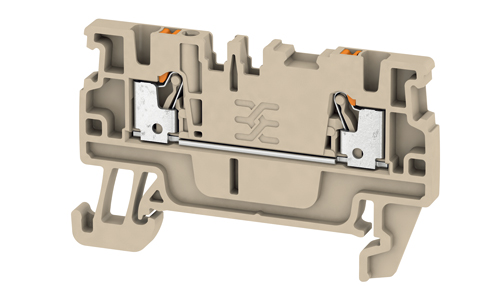

Easy wiring by Push-in insertion of wires to terminals. This reduces wiring work time by 55% compared to screw type terminals. With Push-In terminals work more efficiently and more productively.

Since the width of the terminal and the pitch between ducts are short, it saves space compared to the screw type terminal block. As a result, the control panel can be downsized.

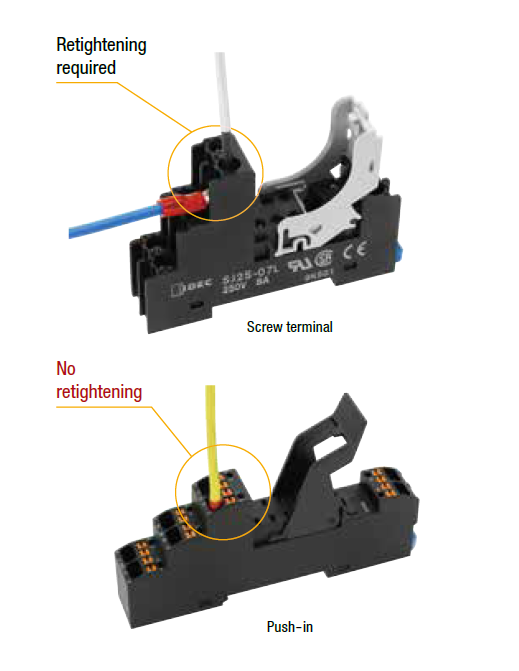

The push-in terminals provide high strength and vibration resistance. The wire connection will not loosen due to vibration like screw terminals. No need to torque terminals after transportation or installation.

You can simulate the man-hours (trial version) by sliding the memory below .

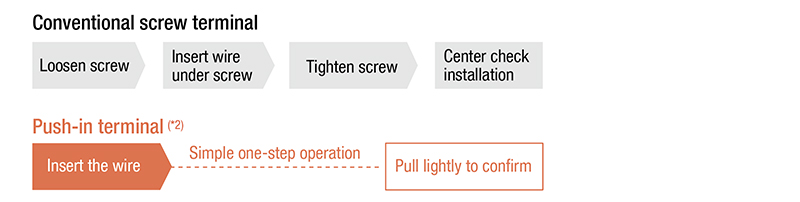

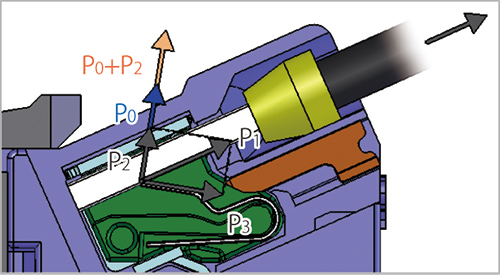

Unique structure provides tensile strength and vibration resistance |

||

BASICSTRUCTURE |

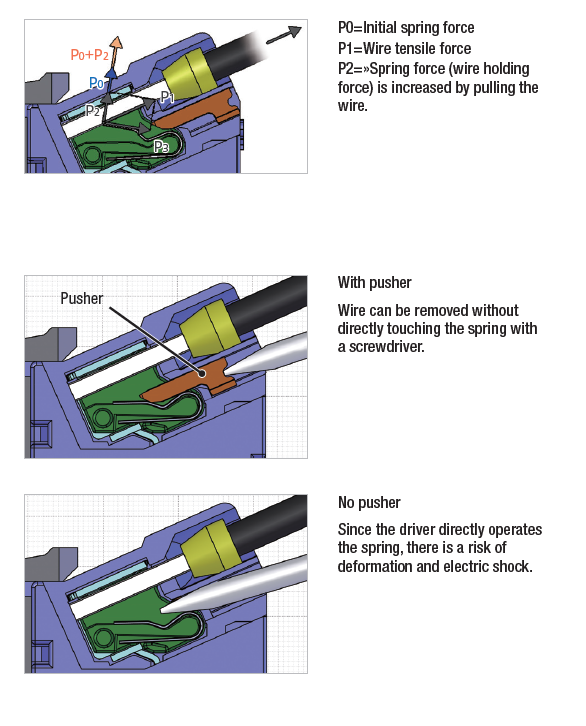

Why fall out?

|

|

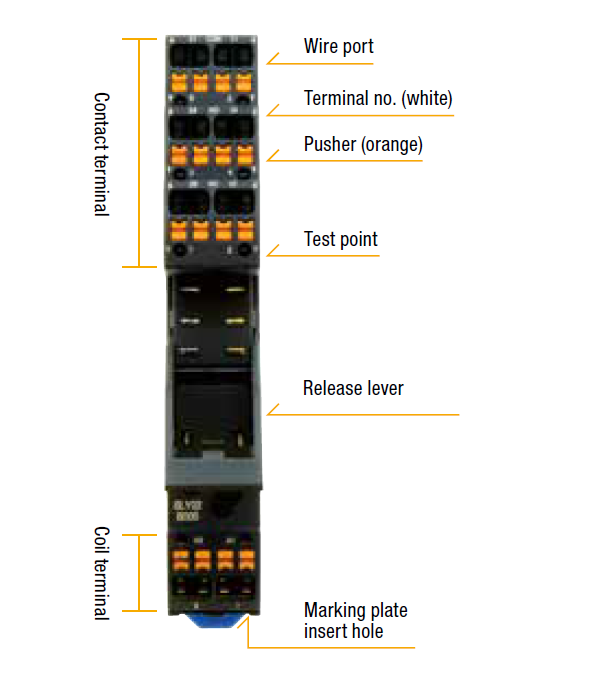

DESIGN

|

Pusher• Prevents loss of wire holding power due to spring deformation • Prevents wire insertion errors • IP20 finger protection structure • No need to touch the conductive part directly with a screwdriver |

|

Structure that increases the wire holding force as it is pulled

P0 = Initial spring force

P1 = Wire tensile force

P2 = Spring force (wire holding force) increases by pulling the wire

Structure that receives the force is made of metal

With the reliable reliability of Push-in products, we propose a method for stable operation of production equipment at the production site.

We propose ways to reduce man-hours in all situations, from equipment assembly to installation and maintenance.

Yes. It is possible.

Ideal for single wire connections that are often used for building installations. If the conductor is rigid enough, it can be connected by simply inserting it by hand without using a tool. Check the applicable wire cross-sectional area of "single wire" described in the catalog.