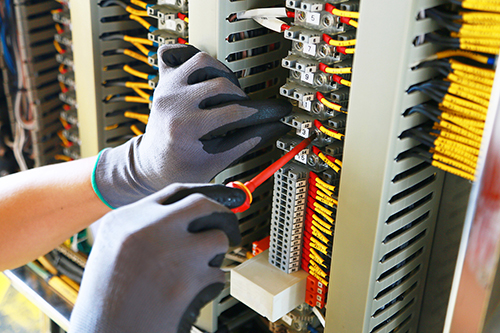

One of the tasks in regular repair is to tighten the screws. Loosening or dropping of screws may cause a fire or stop the operation of equipment due to poor continuity, so it is taken as a countermeasure, but a lot of man-hours are required here. Now that the working population is declining, improving the efficiency of maintenance work such as screw tightening work is a major issue.

Push-in solves that problem.

The push-in type is "screwless", so there is no need to retighten.

In addition, IDEC's Push-in has a unique structure that has strong tensile strength and is resistant to vibration, so there is no need to worry about disconnection even with one-step wiring (* 1) just by inserting it.

Conventionally, the wiring to the control panel uses a screw type terminal block. When installing with a screw type, torque management is difficult because the tightening torque differs depending on the screw size and product. In addition, since it is necessary to hold the screwdriver, screws, and electric wires with both hands, it depends largely on the familiarity and experience of the workers, and the wiring work time varies depending on the workers.

With the push-in type, stable wiring work can be performed because it is easy to insert (* 1), so it is possible to reduce variations in wiring quality without relying on the experience of workers. Achieves stable wiring quality with "safety, security, and speed wiring per second".

Push-in is a simple wiring that not only achieves high wiring quality, but also realizes a significant reduction in wiring man-hours. Man-hours can be reduced just by changing the wiring method to Push-in.

By simulating the wiring man-hours for the screw type and push-in type, we were able to reduce the man-hours for wiring work by 77% and tightening work by 50%.

Donec ullamcorper nulla non metus auctor fringilla. Vestibulum id ligula porta felis euismod semper.

Donec ullamcorper nulla non metus auctor fringilla. Vestibulum id ligula porta felis euismod semper.

With supporting text below as a natural lead-in to additional content.

Go somewhereWith supporting text below as a natural lead-in to additional content.

Go somewhere