Wiring with conventional screw terminals requires the steps of (1) removing the screw, (2) passing the screw through the crimp terminal, and (3) tightening the screw.

Moreover, it is necessary not only to tighten but also to tighten with an appropriate torque according to the product.

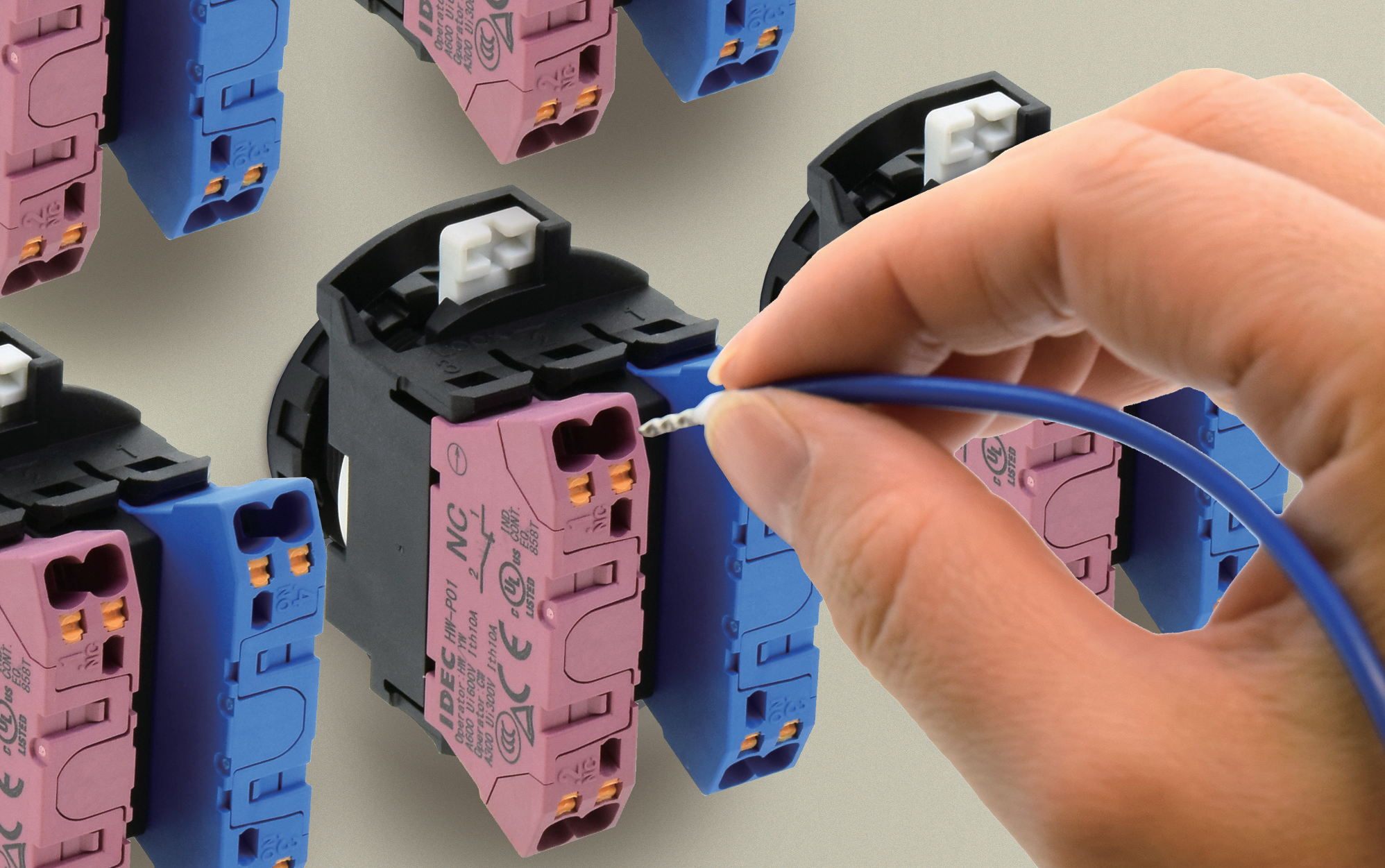

When using the push-in type, wiring is possible without torque management because it is easy wiring (* 1) just by inserting it. With "safety, security, and speed wiring per second," the push-in type can greatly contribute to the efficiency of wiring work.

The assembled equipment and facilities are transported to the customer by truck or ship. During its transportation, vibrations of various sizes will be applied to the device.

In the case of a screw type terminal block, if there is insufficient tightening, the screws will loosen due to vibration, which will eventually lead to equipment malfunction.

What about push-in terminal blocks?

This does not use screws, so there are no loose elements. Since the structure holds down the wire with the load of the spring, there is no need to worry about the wiring loosening due to vibration.

One-step wiring (* 1) that just inserts contributes to the efficiency of shipping work.

Various man-hours are required to install the device.

In the past, detailed work such as rewiring, checking for screw drop, and tightening to prevent loosening was essential before installing and operating the equipment.

If this is a push-in type, there is no need for screw drop or tightening work, so it is possible to omit these work steps.

In addition, there is no worry that the wiring will come off due to the high tensile strength. The one-step wiring (* 1) technology that just inserts produces many merits.

Push-in is a simple wiring that not only achieves high wiring quality, but also provides a significant reduction in wiring man-hours. Man-hours can be reduced just by changing the wiring method to Push-in.

By simulating the wiring man-hours for the screw type and push-in type, we were able to see a reduction in the man-hours for wiring work by 77% and tightening work by 50%.

Donec ullamcorper nulla non metus auctor fringilla. Vestibulum id ligula porta felis euismod semper.

With supporting text below as a natural lead-in to additional content.

Go somewhereWith supporting text below as a natural lead-in to additional content.

Go somewhere