Solutions

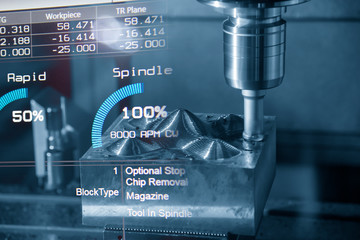

Machine Authorization

Some commercial and industrial equipment needs constant interaction from employees to load and unload materials and parts. Even highly automated machines and systems require occasional attention from operators, maintenance technicians, and supervisors. In these hard-working environments, what is the best way to ensure people are performing these tasks most effectively? Smart RFID systems enable efficient operations.

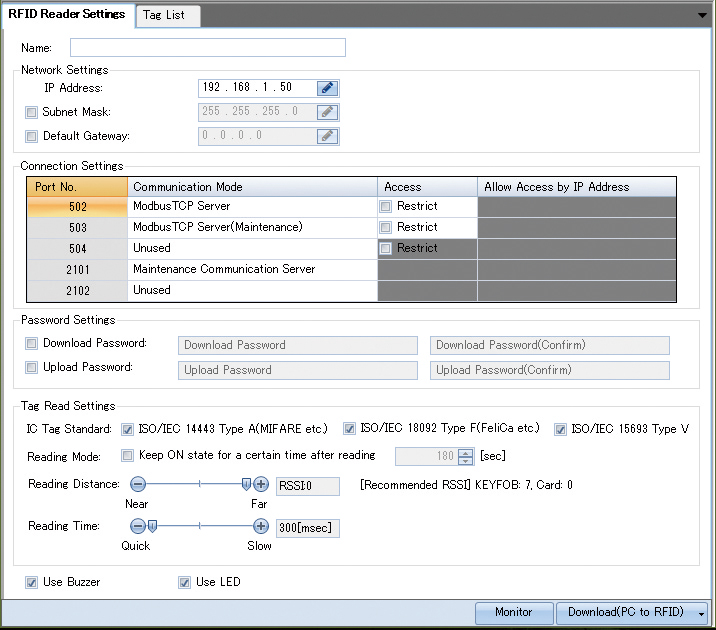

Access Control

Many people are familiar with RFID cards used for building or garage access. However, standard devices won’t hold up to heavy commercial or industrial use and may not integrate smoothly with typical industrial automation platforms. Whether the goal is controlling and tracking access to an industrial job site, a factory building, or an equipment work cell, industrial-grade RFID tags and smart readers are the secure and reliable way for monitoring and controlling personnel movements.

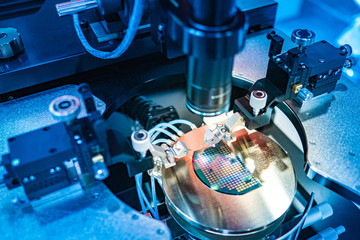

Clean Rooms and Hygienic Areas

Clean rooms and/or hygienic areas are specially constructed areas for fabricating delicate electronics, processing pharmaceuticals, processing foods and beverages, and performing other sensitive activities. In these locations, minimizing the risk of contamination due to foreign objects or particles is a leading consideration. Smart RFID readers built to withstand these washdown areas are a clean, simple, and no-contact method for handling worker access and equipment authorization in these demanding locations.

Industrial Safety

Personnel are trained to work safely in various facility locations, with machinery, and sometimes on or around heavy equipment and vehicles. Designers are always looking for additional guarding and automation methods to improve worker safety and ensure the right personnel are taking the right actions. Smart RFID readers and the associated tags are a practical reliable way for facilitating and tracking safe work.