IDEC emergency stop switches utilize exclusive “Safe Break Action” technology that provides greater levels of human safety and has transformed the way E-stops are designed.

Conventional E-stop switches are designed with spring pressure on the Normally Closed (NC) contacts, keeping them in the closed position and allowing a machine to operate. But improper installation or excessive force to the button in an emergency may break or dislodge a vital part, causing the spring-loaded contact to stay closed. This situation renders the E-stop incapable of stopping the machine, and can lead to catastrophic events, personal injury and possible loss of life.

IDEC X-series E-stops use “Safe Break Action,” which reverses the energy direction and uses spring-pressure to guarantee that the NC contacts will open if the emergency switch is damaged or the contact blocks separate due to excessive force. In a life-threatening situation, you can trust IDEC E-stops to keep your personnel safe!

Internal view while removing the contact block

When the contact block is removed from the operator, the main contact (NC) is forced to open (OFF). When removing the contact block, the cam provides a direct opening action to open the contact.

Exceeding all Global Standards for Emergency Stop Switches

With X-series emergency stop switches, the potential energy level of the latched status is lower than that of normal status. In the event the switch is damaged due to excessive shocks, the NC contacts will turn off, thus stopping the machine (patented design).

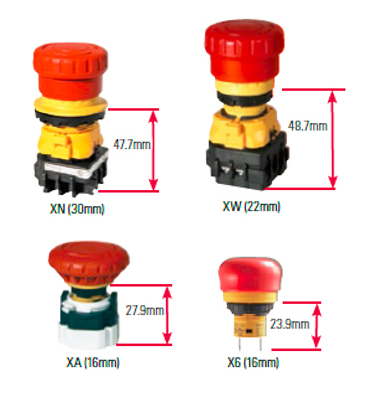

IDEC HW, XW and XN series E-stops are listed by Underwriters Laboratories (UL) as category NISD emergency stop devices, while the XA and X6 series are UL NISD2 recognized. These ratings allow emergency stop devices intended to be installed in a machine control system, to perform a Category 0 or Category 1 stop function as defined in the ANSI/ NFPA79, “Electrical Standard for Industrial Machinery.” These devices have been investigated for functionality, in addition to fire and electrical shock safety.

![]()

The X-series E-stops can be reset either by pulling or turning the button (Push-to-lock, Pull/Turn-to-reset). With traditional E-stops, you choose between Push-Pull or Push-lock Turn Reset. With the IDEC X-series E-stops, you get both in one switch (except XN4E, which is only Push-lock Turn Reset), providing an extra level of protection when unforeseen events occur.

Eliminate the chance of an accidental resetting. The XN series of emergency stops were specifically developed to prevent unauthorized or accidental resetting of latched E-stop switches. XN4E E-stops offer a higher level of function and safety by allowing the use of up to twelve personal padlocks. With a conventional E-stop, a technician presses the emergency stop then works on the machine, but nothing stops someone else from accidentally restarting the machine while the technician is still working. Not so with XN4E! These E-stops prevent accidents by allowing each technician to place a padlock on the E-stop, preventing resetting of the E-stop and restarting of the machine, until all padlocks have been removed by their respective owners. It’s a simple way to keep everyone safe.

|

|

|

|

|

| Idea for smaller machines, XA series mounts in a 16mm panel hole and has shallow depth behind the panel. | XW series features rugged construction, and mount in a 22mm panel hole. They are secured from the back of the panel, so they cannot be defeated. | HW series estops offer a wide variety of options and can accomodate up to 6 contacts. Ideal for general purpose applications in a broad range of industries. | Robust construction with shallow panel depth. | |

| Panel Hole Size | 16mm | 22mm | 22mm | 30mm |

| Operator Sizes | 29mm, 40mm | 40mm, 60mm | 29mm, 40mm, 60mm | 40mm, 60mm |

| Number of Contacts | up to 4 | up to 4 | up to 6 | up to 4 |

| Terminal Connection | PCB, Solder, Solder/Tab | Screw | Screw | Screw |

| Operation | Push to lock; pull or turn to reset | Push to lock; pull or turn to reset | Push to lock; pull, turn, or key to reset | Push to lock; pull or turn to reset |

| Illuminated Option | Yes | Yes | Yes | Yes |

| Lockout Option | - | - | - | - |

| Smooth Operator | - | - | - | - |

| Safebreak Technology | Yes | Yes | - | Yes |

| Type 4X | Yes | Yes | Yes | Yes |

| Hazardous Location | - | - | - | - |

|

|

|

|

|

| Eronomic smooth button with an elegant design ideal for applications that require cleanliness and a prevention of dust buildup. Smallest in its class. | The XW Smooth series features a large ergonomic button that resists dirt and dust buildup. | The XN4E series adds an additional layer of safety -- a lockout feature that prevents unauthorized resetting of a latched e-stop. | Designed for use in hazardous locations. Class 1 Zone 1 rating along with UL, Atex, and IECEX approvals. Ideal for applications in areas with explosive gases such as oil and gas, petrochemical, painting and many others. | |

| Panel Hole Size | 16mm | 22mm | 30mm | 30mm |

| Operator Sizes | 30mm, 40mm | 38mm | 44mm | 40mm |

| Number of Contacts | up to 2 | up to 4 | up to 4 | up to 3 |

| Terminal Connection | Solder/Tab | Screw | Screw | Screw |

| Operation | Push to lock; pull or turn to reset | Push to lock; pull or turn to reset | Push to lock; pull or turn to reset | Push to lock; pull or turn to reset |

| Illuminated Option | - | Yes | Yes | - |

| Lockout Option | - | - | Yes | - |

| Smooth Operator | Yes | Yes | - | - |

| Safebreak Techonology | Yes | Yes | Yes | Yes |

| Type 4X | Yes | Yes | - | Yes |

| Hazardous Location | - | - | - | Yes |

Get in touch with us via the links below. We will respond to you shortly.

IDEC Corporation

1175 Elko Drive

Sunnyvale, CA 94089-2209

(408) 747-0550

(800) 262-IDEC (4332)

Have questions about our products? Get in touch with the IDEC Technical Support team.

Get help, request product demonstrations, or ask for your nearest sales engineer or distributor