To address labor shortages, diverse workforce needs, and improved working conditions, collaborative robots and AGV/AMR usage are progressing in all industries. Along with this, the industry requirements are evolving, focusing on miniaturization, indoor-outdoor adaptability, and new standards compliance.

IDEC responds to these demands with an innovative emergency stop switch. This small, high-performing solution demonstrates IDEC's commitment to offering innovative solutions that meet the industry's constantly evolving needs.

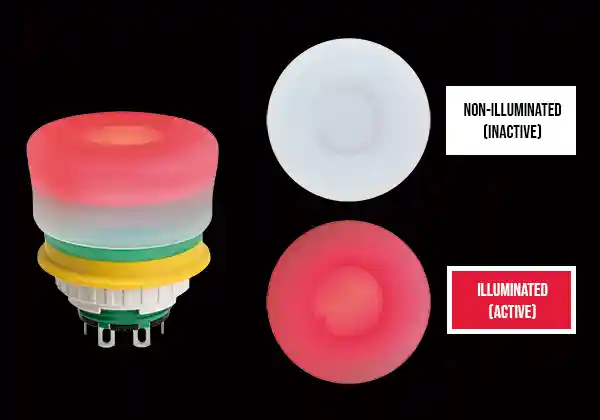

ISO 13850:2015, Section 4.3.8, states that when installing emergency stop devices on detachable or cableless controllers, measures shall be applied to avoid confusion between enabled and disabled states.

IDEC has developed a product that applies one of the measures required, "Change the color of effective emergency stop equipment by lighting".

(* Excerpts and summary of ISO13850:2015)

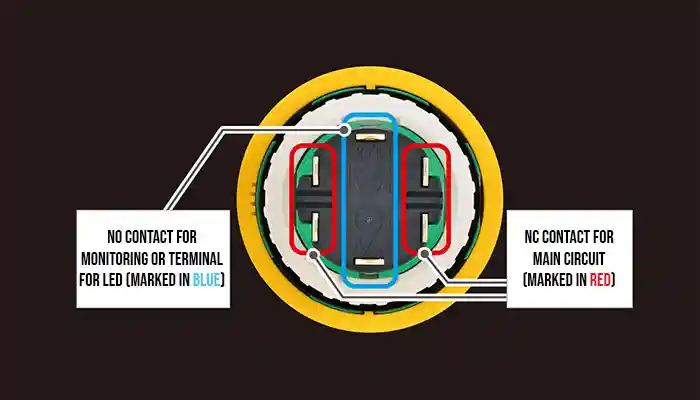

Compact unibody structure with 3-terminal configuration suitable for a wide range of applications in limited space.

One contact (blue) can be used as a lamp terminal or as a NO contact for monitoring.

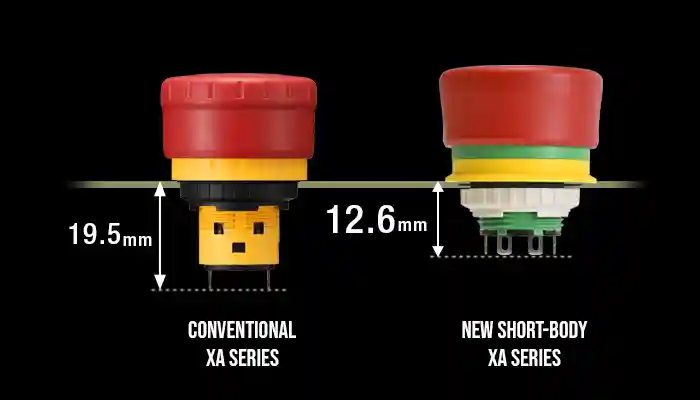

Panel depth: 12.6 mm (soldering terminal), 17.0 mm (tab terminal)

Designed with the shortest body among multiple generations of IDEC emergency stop switches, this E-stop helps users save space behind the panel for their application.

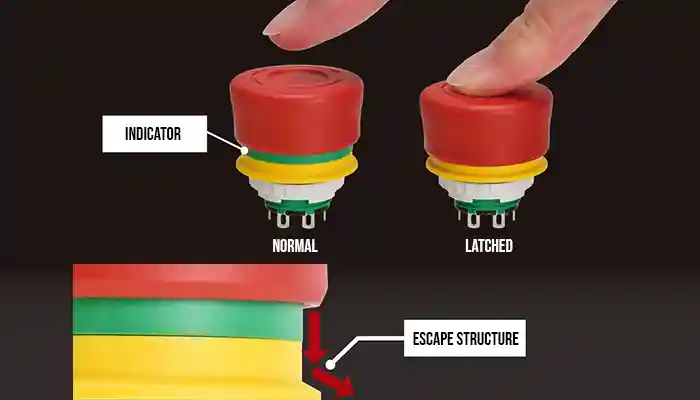

The indicator (green area) visible from the side enables the user to check the operating status of the switch at a glance.

Also, an escape structure prevents foreign objects from being caught during operation, ensuring a smooth activation of the E-stop in an emergency situation.

XA/XW series E-stops are UL type 4X certified, making them the ideal E-stops for use in wet, windy, and snowy environments.*

* Not certified for use in all outdoor environments.

Adopts IDEC's unique safety structure (* 1) 「"Safety PotentialTM」to pursue safety.

Even if a problem occurs somewhere in the switch, it can prevent the machine from operating again, which helps to further ensure the safety of workers in an emergency.

In addition to the requirements of international safety standards, safety is considered more than the requirements of international safety standards, such as always failing to fail on the safe side in the event of damage due to excessive force or impact. It is the best safety equipment for building a safety system.

* 1) February 2023 IDEC survey

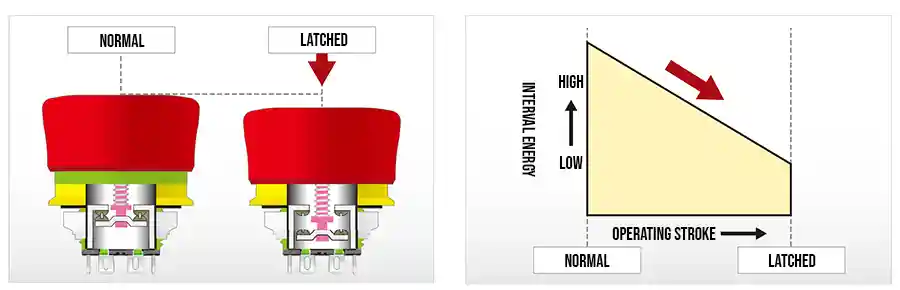

In the X series, the internal energy is lower in the locked (latching) state than in the normal state. If the switch is damaged due to excessive force or impact, the main contact (NC contact) will try to shift to OFF (safety side).

16mm XA push lock pull or turn reset switch (non-illuminated)

| Appearance | Model Number (Order Model Number) | Contact Point | Terminal Shape | Button Color |

|---|---|---|---|---|

|

XA1E-BV3SG01※ | 1b | Soldering terminal |

R(red)

RH(bright red)

|

| XA1E-BV3SG01T※ | Soldering tab 110 terminal | |||

| XA1E-BV3SG02※ | 2b | Soldering terminal | ||

| XA1E-BV3SG02T※ | Soldering tab 110 terminal | |||

| XA1E-BV3SG12※ | 1a2b | Soldering terminal | ||

| XA1E-BV3SG12T※ | Soldering tab 110 terminal |

22mm XW push lock pull or turn reset switch (non-illuminated)

| Appearance | Model Number(Order Model Number) | Contact Point | Terminal Shape | Button Color |

|---|---|---|---|---|

|

XW1E-BV3SG01※ | 1b | Soldering terminal |

R(red)

RH(bright red)

|

| XW1E-BV3SG01T※ | Soldering tab 110 terminal | |||

| XW1E-BV3SG02※ | 2b | Soldering terminal | ||

| XW1E-BV3SG02T※ | Soldering tab 110 terminal | |||

| XW1E-BV3SG12※ | 1a2b | Soldering terminal | ||

| XW1E-BV3SG12T※ | Soldering tab 110 terminal |

16mm XA push lock pull or turn reset switch (illuminated type)

| Appearance | Model Number(Order Model Number) | Contact Point | Terminal Shape | Button Color | Illuminated Color |

|---|---|---|---|---|---|

|

XA1E-LV3SG02Q4R | 2b | Soldering Terminal |

R

(red) |

R

(red) |

| XA1E-LV3SG02Q4TR | Soldering tab 110 terminal | ||||

|

XA1E-LV3SG02Q4WR | 2b | Soldering terminal |

W

(white) (*) |

R

(red) |

| XA1E-LV3SG02Q4TWR | Soldering tab 110 terminal |

22mm XW push lock pull or turn reset switch (illuminated type)

| Appearance | Model Number(Order Model Number) | Contact Point | Terminal Shape | Button Color | Illuminated Color |

|---|---|---|---|---|---|

|

XW1E-LV3SG02Q4R | 2b | Soldering terminal |

R

(red) |

R

(red) |

| XW1E-LV3SG02Q4TR | Soldering tab 110 terminal | ||||

|

XW1E-LV3SG02Q4WR | 2b | Soldering terminal |

W

(white) (*) |

R

(red) |

| XW1E-LV3SG02Q4TWR | Soldering tab 110 terminal |

Emergency stop push button switch used in all industries.

By shortening the body, the applications will expand further.

Pendants and controllers can be further miniaturized

Compatible with impact resistance and weather resistance for semi-outdoor use. Contributing to miniaturization of vehicles

Suitable for outdoor use, shock resistance, and high temperature (ambient temperature up to 70 ° C)

It is also resistant to outdoor use, vibration resistance / shock resistance (malfunction) environment

Understand it from the basics at the IDEC safety equipment course.

Learn about the international safety standards.