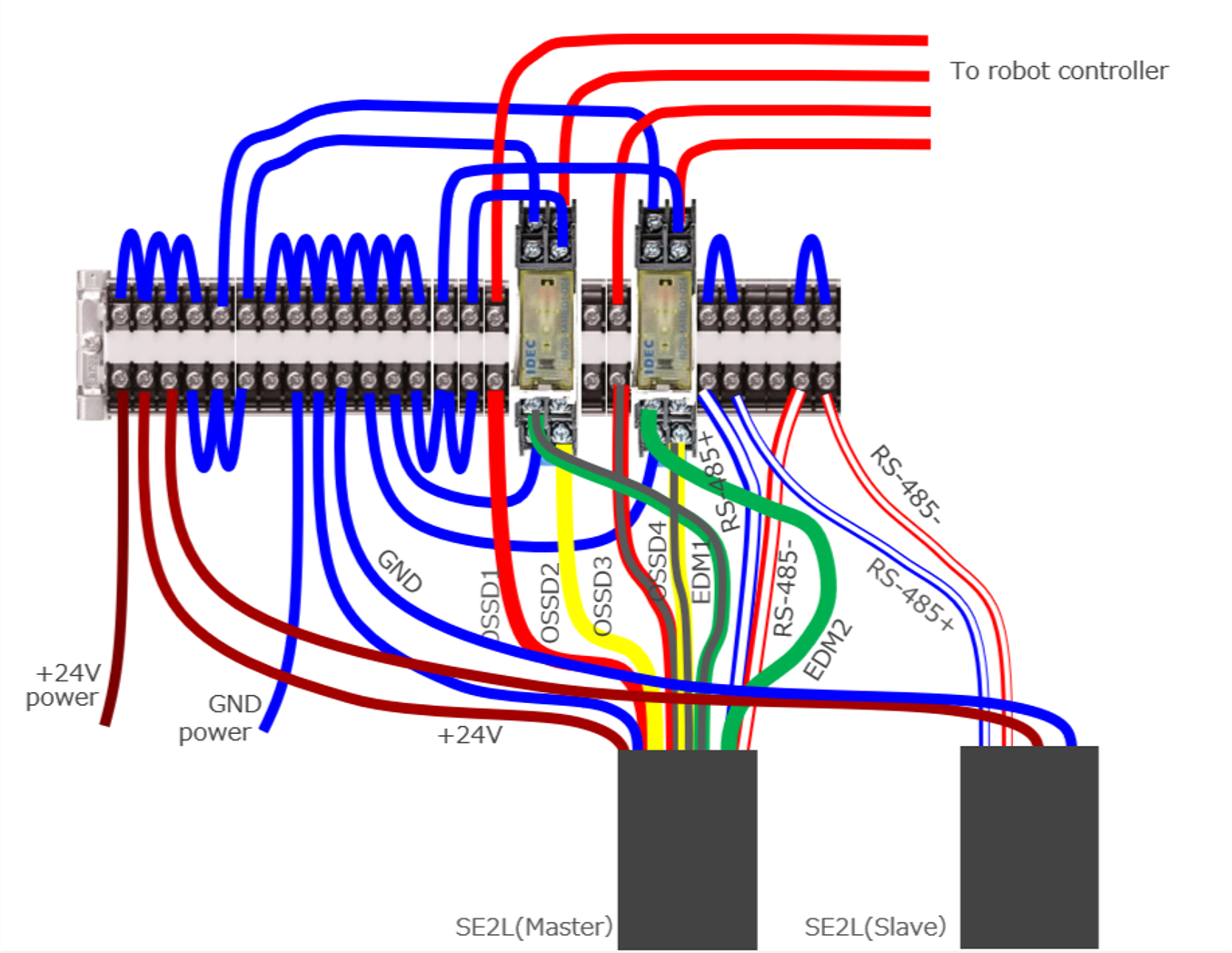

IDEC's SE2L safety laser scanner streamlines wiring for ease of installation. With its simple and intuitive wire connections, users can save valuable time and effort during setup. This scanner is designed with a user-friendly wiring system, making it a convenient choice for those seeking a hassle-free integration process, ultimately reducing installation time and costs.

Before

Wiring inside the control panel or robot controller

After

Reduced wiring, space, man-hours, and maintenance

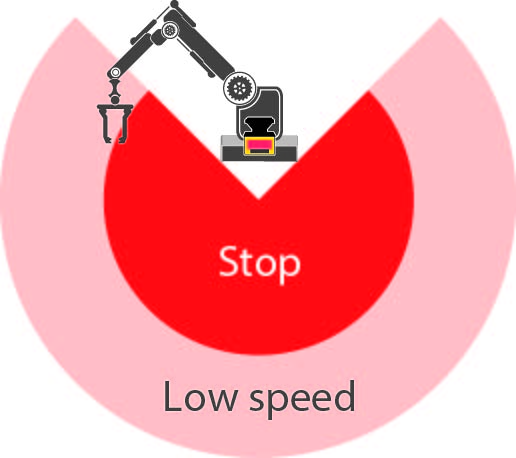

IDEC's SE2L safety laser scanner excels in presence detection, reliably identifying the presence of objects or individuals within its defined safety zones. With precision and speed, it reacts promptly to any intrusion, making it an ideal choice for ensuring safety in collaborative robot applications. Its ability to distinguish between objects and humans minimizes false alarms, allowing cobots to operate efficiently and safely in close proximity to human workers. The SE2L's presence detection functionality is a pivotal component in creating a secure environment for human-robot interaction, fostering trust and productivity in the workspace.

IDEC's SE2L safety laser scanner is a key player in collision avoidance strategies. Its responsive capabilities enable real-time monitoring and immediate response to potential collisions between a cobot and nearby objects or personnel. By creating protective zones and dynamically adjusting the robot's movements, the scanner ensures safe and accident-free human-cobot interactions. This collision avoidance functionality adds an essential layer of protection, fostering a collaborative workspace where humans and robots can work side by side with confidence and efficiency.

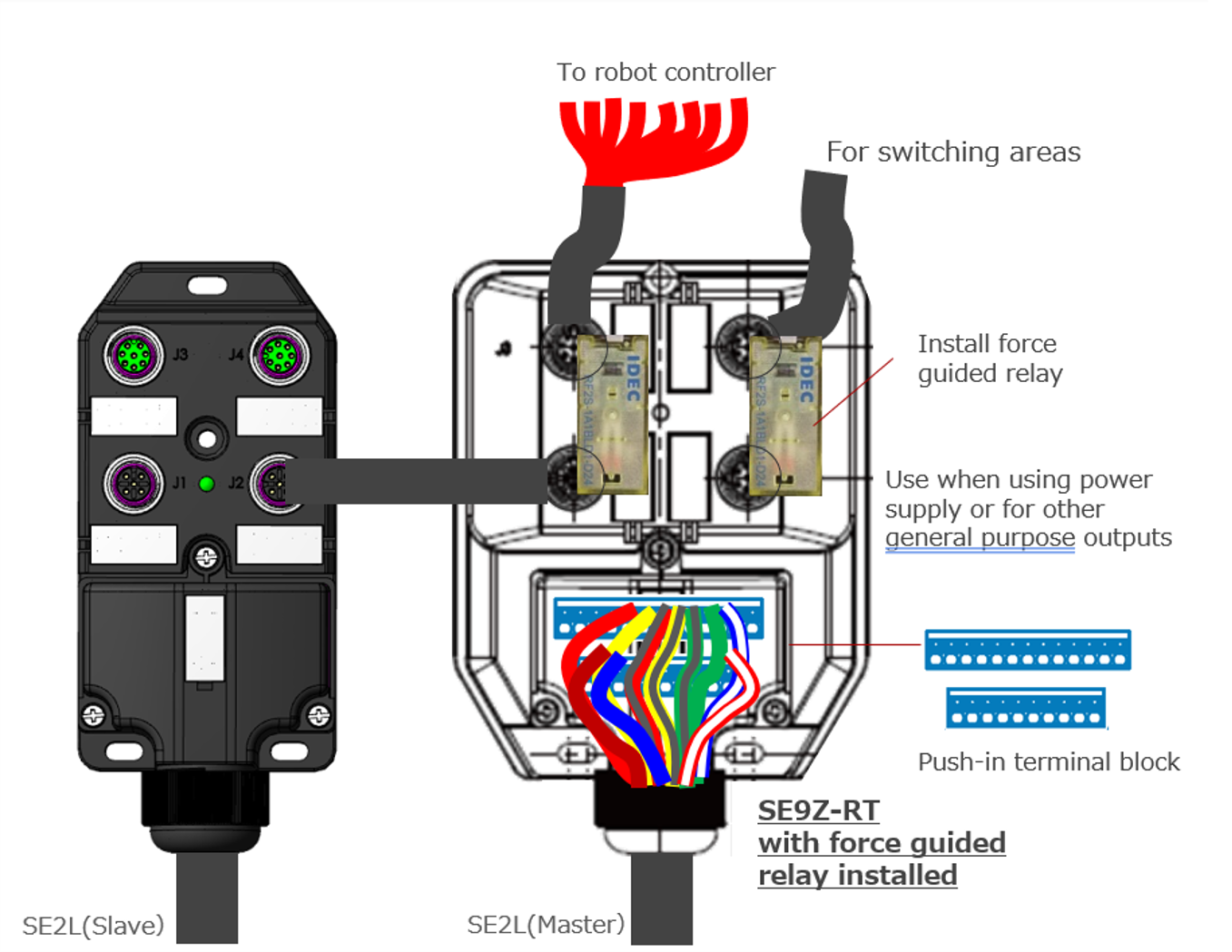

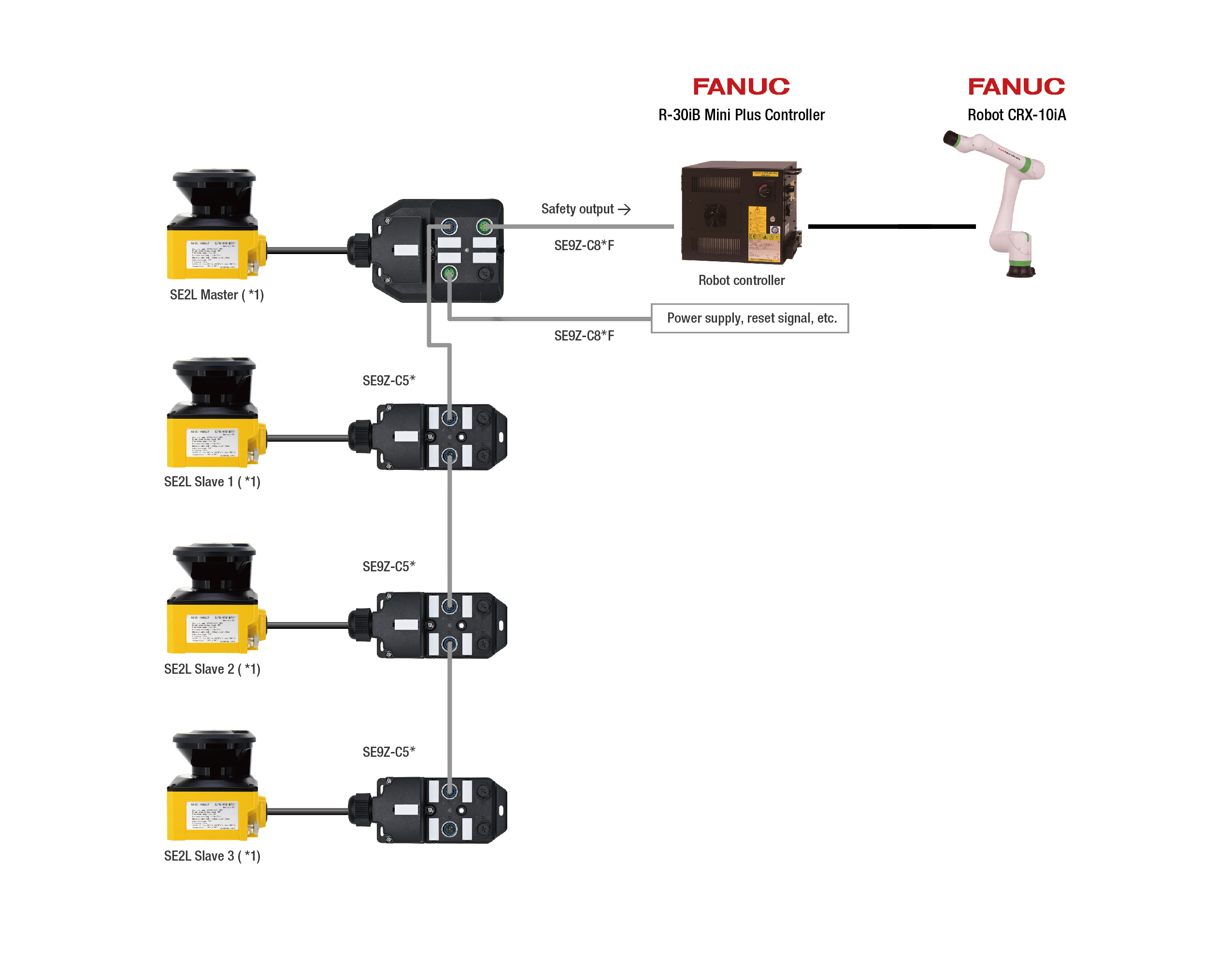

IDEC's SE2L safety laser scanner offers master-slave functionality, allowing multiple scanners to work in harmony to enhance safety and coverage. In this configuration, one scanner acts as the master, while others become slaves, creating a networked safety system that collectively monitors a more extensive workspace. This collaborative setup is particularly advantageous in robot applications requiring comprehensive safety monitoring, ensuring that the entire workspace is continuously and effectively safeguarded while maintaining optimal flexibility in human-robot collaboration.

Master-slave connections allow input and output to be integrated, so up to four units can be handled as if they were one unit.

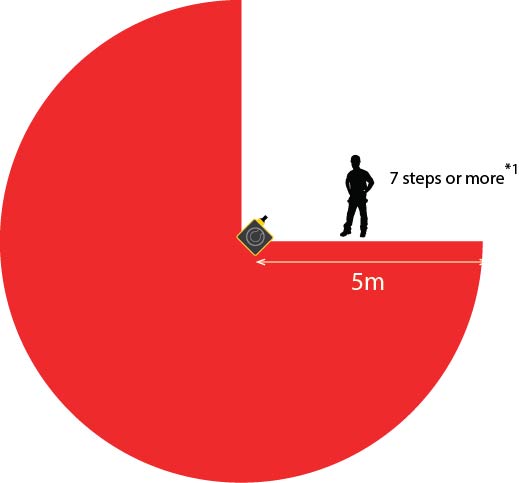

A maximum of four SE2Ls can be interconnected using RS-485 for master/slave operation. In this case, you surround your cobot with a 360° safety zone.

FANUC CRX-proven safety solution, IDEC's SE2L safety laser scanner is a versatile and reliable safety device that is well-suited for use with collaborative robots, or cobots. Here are some points highlighting why it is a great choice for your cobot application:

The SE2L is designed with a compact form factor and is lightweight, making it easy to install on or near a cobot without adding significant weight or taking up much space.

The scanner is straightforward to set up and install, which is important when working with cobots that need quick deployment and reconfiguration. It can be easily integrated with various cobot control systems, making it a versatile choice for a wide range of collaborative robot models.

The SE2L allows for the definition of multiple safety zones, which can be customized to match the specific operating range and workspace of the cobot. This flexibility ensures that cobot safety is maintained while optimizing its work area.

The SE2L offers fast response times to stop the cobot when an operator or object enters a predefined safety zone. This quick reaction time helps prevent accidents and enhances safety in human-robot collaboration scenarios.

The SE2L can be used to monitor multiple zones simultaneously, which is beneficial in cobot applications where the robot needs to operate in various areas and directions.

IDEC provides user-friendly software for configuration and monitoring, allowing for easy adaptation of the safety scanner to different cobot tasks and workspaces.

The SE2L is equipped with advanced safety features, such as dynamic and static muting, and it can distinguish between objects and humans, reducing false alarms and enhancing the safety of cobot interactions with human workers.

The SE2L's capabilities make it suitable for monitoring and maintaining safety in collaborative workspaces where cobots and human operators work closely together. It helps ensure that cobots stop or slow down when necessary to prevent collisions.

IDEC's SE2L complies with international safety standards, such as ISO 13849 and ISO 14119, ensuring that it meets stringent safety requirements for collaborative robot applications.

IDEC's SE2L offers an affordable solution for ensuring the safety of cobots in various industries, making it a cost-effective choice for businesses looking to implement collaborative automation.

" IDEC's SE2L safety laser scanner is perfectly suitable for use with cobots, like the FANUC cobot CRX, due to its compact design, customizable safety zones, responsiveness, advanced features, and compliance with safety standards. It plays a crucial role in enhancing the safety of cobot coworking while enabling efficient human-robot collaboration. "

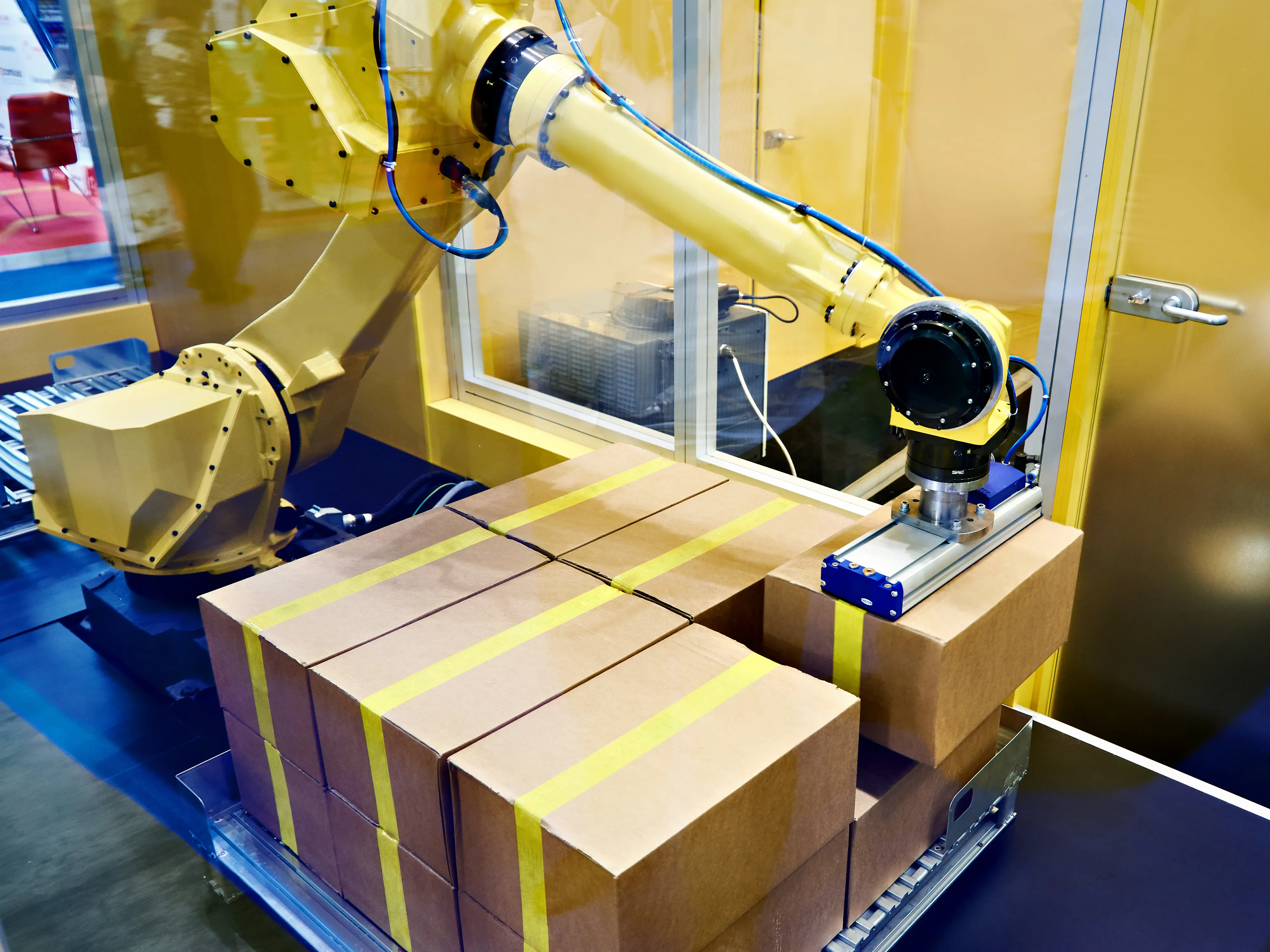

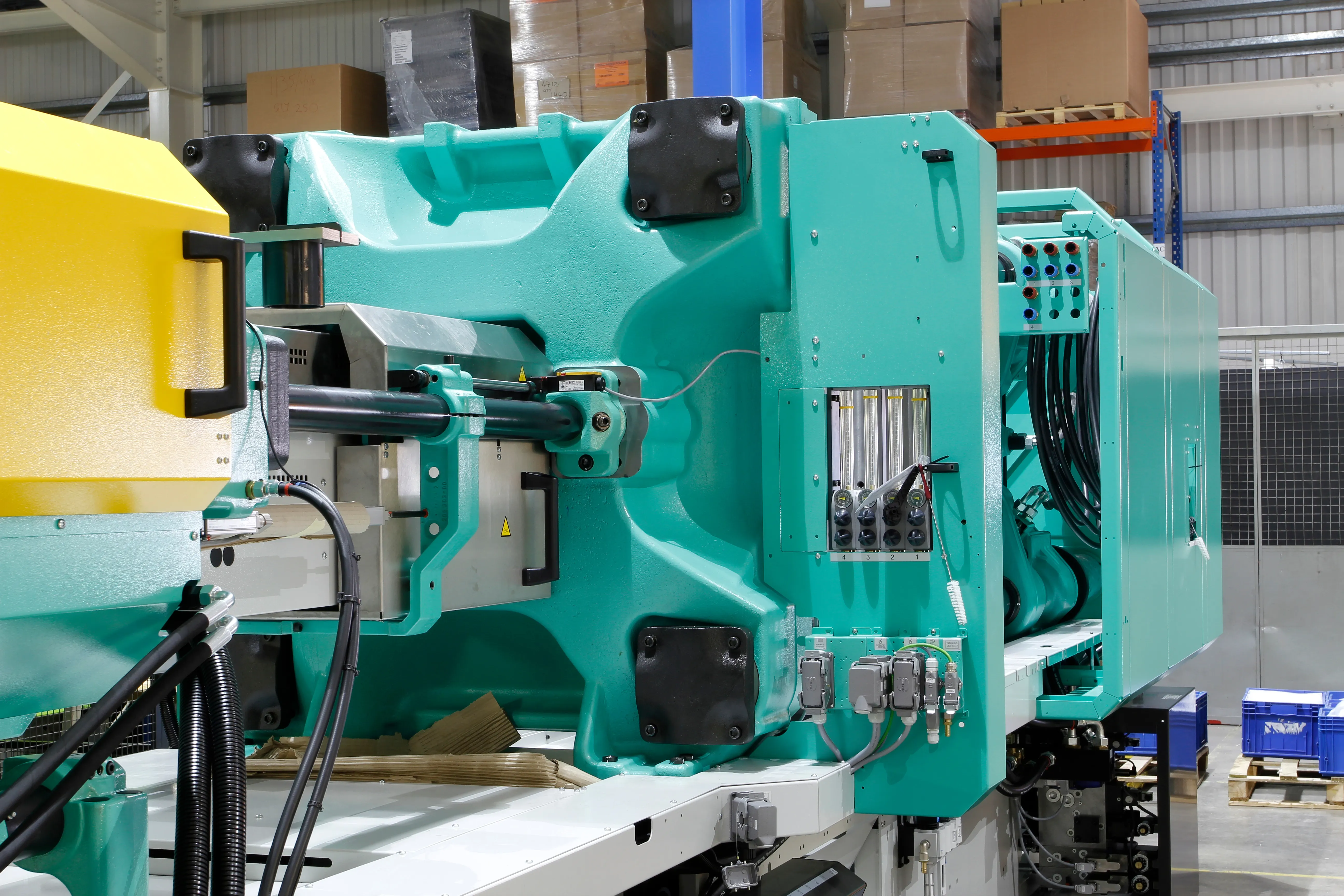

IDEC's SE2L safety laser scanner is a highly versatile and advanced safety device that is perfectly suited for use with industrial robots. Its compact design and advanced detection capabilities make it an ideal solution for safeguarding workers and equipment in a variety of industrial settings. With its long-range detection and customizable safety zones, the SE2L scanner can be easily integrated into the complex movements of industrial robots, ensuring that they stop in time to prevent collisions and potential accidents. Its rugged construction and ability to withstand harsh environments also make it a reliable choice for use in demanding industrial applications. Overall, the SE2L safety laser scanner is a valuable safety tool for enhancing the performance of industrial robots and ensuring a safe working environment.

IDEC's SE2L safety laser scanner is an ideal safety solution for Automated Guided Vehicles (AGV) and Autonomous Mobile Robots (AMR). With a compact design and a range of advanced features, it is uniquely suited for use in fast-moving and dynamic environments. Its multiple scanning layers and advanced safety functions, such as the ability to detect moving objects and create warning zones, ensure maximum safety for both the AGV/AMR and surrounding personnel. Additionally, the SE2L scanner's high-speed scanning and customizable protective fields make it perfect for use in high-traffic areas and tight spaces. Its versatility and reliability make it an excellent choice for any AGV/AMR application, providing enhanced safety and efficiency.

IDEC's SE2L safety laser scanner is an ideal solution for pinch prevention in machine tools. With its compact size and long range detection capabilities, it can easily be integrated into the moving parts of a machine tool to detect any potential danger zones where operators could get their hands caught. The scanner's advanced technology allows for customizable field configuration, ensuring it is only triggered when necessary, minimizing false alarms and maintaining machine productivity. Its reliable and fast response time also ensures potential pinch hazards are detected and avoided in real-time, providing a safe working environment for machine operators. Overall, the SE2L safety laser scanner is a highly applicable solution for pinch prevention in machine tools, providing peace of mind for both operators and employers.

IDEC's SE2L safety laser scanner offers many benefits that make it an ideal replacement for traditional light curtains in assembly line safety applications. With its 270-degree scanning angle and flexible configuration options, the SE2L can provide complete coverage of the work area, ensuring the safety of both workers and machinery. Additionally, with its small form factor and easy installation, the SE2L is a cost-effective solution that can easily be integrated into existing assembly lines. Its advanced safety features, such as muting and blanking capabilities, also make it a versatile choice for a variety of assembly line setups. Overall, the SE2L offers improved safety, increased efficiency, and cost savings, making it a highly applicable solution for assembly lines in need of a reliable and modern safety system.