MicroSmart PLC All-in-One

Power, Performance, Connectivity

IDEC brought some of the first micro-Programmable Logic Controllers to the market, and has been meeting your changing control automation needs for decades. Our next generation MicroSmart FC6A , a powerful micro PLC with the features of a PAC (programmable automation controller) in a low-cost and small form factor, making it an ideal fit for demanding applications.

MicroSmart FC6A All-in-One

Design

Removable Terminal Blocks

The MicroSmart PLC has removable I/O and power terminal blocks to simplify wiring, installation and module replacement. A terminal block can be completely wired, and then plugged into a module. Spring clamp terminal blocks are optional.

SD Memory Slot

An SD memory card can be plugged into the MicroSmart PLC SD port. This card can be used for data logging, program storage/transfer, firmware updating or recipe storage.

RJ45 Ethernet Port

The MicroSmart PLC has a built in RJ45 Ethernet port which supports the Modbus TCP protocol. Easily and remotely connect to the PLC using WindLDR software for program download, update and monitor.

USB Bus Power

The MicroSmart PLC’s USB port can be used to transfer its software program from a PC to the CPU without connecting a power supply. The USB connection from the PC also provides power to the CPU, so it doesn’t have to be plugged in for program upload or download, or for monitoring by a PC.

RJ45 RS232C/ RS485 Serial Port

The MicroSmart PLC has a built in RJ45 serial port selectable by the user for either RS232C or RS485 communications. A plug-in cartridge adds an additional RS232C/RS485 port. The serial port supports the Modbus User and RTU protocols.

Replaceable Battery

The MicroSmart PLC’s battery can be easily replaced. Warning of low battery level is provided both at the CPU via an LED, and through a special data register which can be used to trigger an alarm on the HMI or send an email alert.

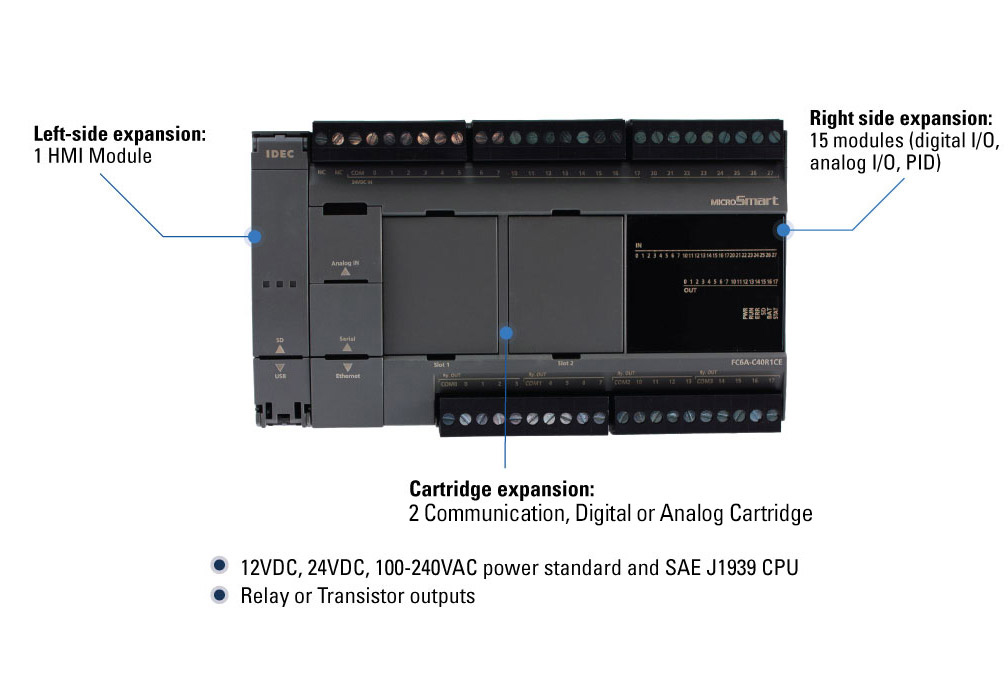

Digital and Analog Cartridges solution

Each analog cartridge has two analog I/O points, either two inputs or outputs. Whereas digital cartridge has four inputs or outputs. This makes the MicroSmart FC6A an ideal solution for applications requiring minimal digital or analog I/O in a compact form allowing space-saving and cost effective.

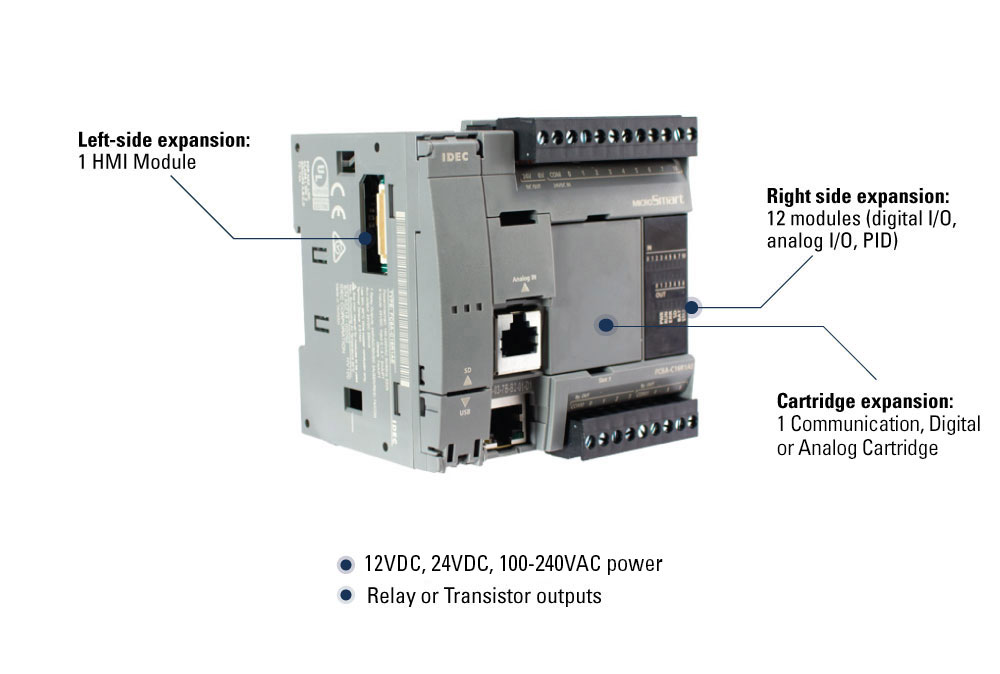

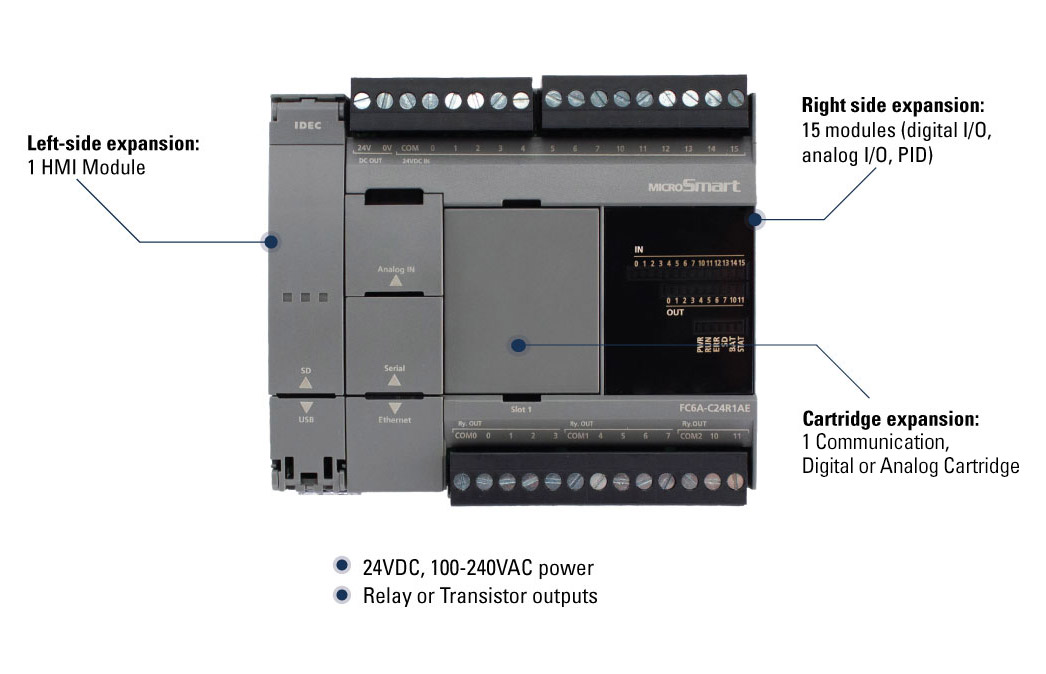

Easy to expand Communication Ports

One communication cartridge can be added to the MicroSmart PLC 16 and 24 I/O models, and two communication cartridges can be added to the MicroSmart PLC 40 I/O model. Each cartridge has one serial port.

Up to 15 Expansion Modules without limitation

Up to 12 expansion modules can be added to the MicroSmart PLC 16 I/O model, and up to 15 expansion modules can be added to the MicroSmart PLC 24 and 40 I/O models. These modules can be of any type with no restrictions as to the number of analog and specialty modules.

HMI Module

An optional HMI module can be added to provide operator interface. The HMI module can also accommodate an optional plug-in analog cartridge, and it has an integral Ethernet port. IoT capability is provided by custom web pages. Now you can create sophisticate and informational web pages using WindLDR built-in web page editor with drag & drop simplicity. These web pages can then be accessed via any web browser running on any Internet-connected device such as a remote PC, a tablet or a smartphone.

Unmatched Performance

Fast Execution Time

Processing time for Basic instruction

24 time faster than FC4A

16 time faster than FC5A

Fast I/O Refresh

Comparing a typical setup with CPU, plus 4 digital I/O and 1 analog expansion module, the MicroSmart FC6A takes only 0.4ms to read and update all the expansion I/O. This is extremely fast comparing to other micro PLC. As a result, your system reacts faster and runs more effieciently.6 time faster than FC5A

Large 640KB (80,000 steps) programming memory

Handle large and more sophisticated program for bigger systems

Program Capacity (KByte)

Large Data Memory

The MicroSmart PLC has 1,024 timers, and six of the 512 counters are high-speed at rates up to 100kHz. These capabilities are combined with extensive data and bit memory, double the capacity of a typical micro PLC.

Built-in Real Time Clock

The MicroSmart PLC has a built-in real-time clock. Alternatively, the PLC can obtain time information from an SNTP server for time-based applications such as lighting controls.

Upgradable Firmware for CPU and expansion modules

The CPU and expansion modules have field-upgradeable firmware, making it easy to keep the MicroSmart PLC up to date.

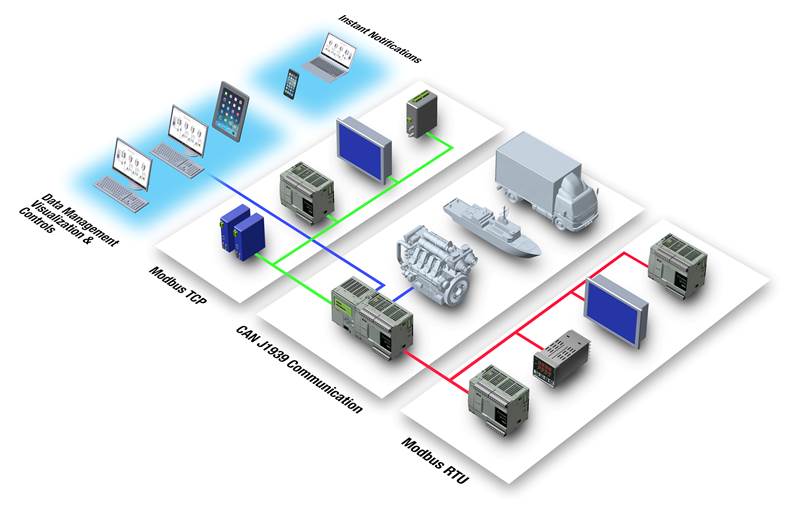

Communication of Choice

Modbus TCP and RTU protocol

FC6A supports both Modbus TCP and RTU. It can be easily be configured to be a Client (master) or Server (slave) on the Modbus network.

CAN J1939 Protocol

The MicroSmart PLC supports the CAN J1939 protocol, commonly used in diesel power train applications, in-vehicle networks for trucks & buses, agriculture & forestry machinery, military and recreational vehicles, and marine navigation systems.

Email and Text Notification

Using HMI module, FC6A MicroSmart can easily be configured to send Email or Text message to your PC or mobile phone. Dynamic values in the PLC can also be incorporated in the body of the email as well to show status conditions Up to 255 email messages can be configured and multiple recipients can be included in the email To and cc fields. Third party email servers such as Gmail or Yahoo can be configured.

Programming

Web Page Editor

WindLDR version 8+ introduced a new Web Page Editor where anyone can use it to create professional and dynamic web pages to monitor and control the MicroSmart FC6A PLC.

Web Page Editor Tutorials

Ever wonder how you can create web page for your PLC without hiring an HTML and Java script expert?

Watch the videos below to see what you can do with web page editor!

Many industrial applications require motion control, but users are often frustrated by the complexity and high cost of implementation. IDEC Corporation and AMCI, an established supplier of motion control systems, have partnered to address this issue by offering a simple yet highly capable stepper motion control system. This AMCI by IDEC product line includes controllers, stepper motors, a combo controller+drive, a combo drive+stepper motor, and the 3-in-1 controller+drive+stepper motor. When combined with an IDEC FC6A PLC and its embedded motion control software modules, these products allow users to quickly and simply implement single- and multi-axis motion control in a wide range of industries and applications.

Many industrial applications require motion control, but users are often frustrated by the complexity and high cost of implementation. IDEC Corporation and AMCI, an established supplier of motion control systems, have partnered to address this issue by offering a simple yet highly capable stepper motion control system. This AMCI by IDEC product line includes controllers, stepper motors, a combo controller+drive, a combo drive+stepper motor, and the 3-in-1 controller+drive+stepper motor. When combined with an IDEC FC6A PLC and its embedded motion control software modules, these products allow users to quickly and simply implement single- and multi-axis motion control in a wide range of industries and applications.

What Makes up a Stepper Motion System?

Click on the products below for more information

FC6A MicroSmart

MicroSmart FC6A , a powerful PLC with up to 520 digital I/O and 126 analog I/O. The MicroSmart FC6A provides the power of a PAC (programmable automation controller) in a low-cost controller with a small form factor, making it an ideal fit for demanding applications. Learn more

Controller

A 2-axis motion controller that can be expanded up to 12 axes. It can accept encoder feedback to provides stall detection and move verification. It includes six discrete inputs for move conditioning and other functions, and four discrete outputs to indicate status and provide diagnostics. Learn more

Drive+Controller

AMCI by IDEC’s integrated Stepper controller+drive combo is a ground-breaking approach to PLC-based motion control systems. With its servo performance in a stepper motion hardware, the IANG1 series can be expanded up to 6 axes Learn more Learn more

Stepper Motor+Drive+Controller

AMCI by IDEC’s controller+drive+motor combo unit provides all-in-one motion control with all the features of the two-axis controller, drive and stepper motor. Learn more

Stepper+Drive

AMCI by IDEC’s motor+drive combo unit can control one to six axes of motion, and it combines all the features of the two-axis controller and the drive into a single unit.. Learn more

Drive+Controller

AMCI by IDEC’s integrated Stepper controller+drive combo is a ground-breaking approach to PLC-based motion control systems. With its servo performance in a stepper motion hardware, the IANG1 series can be expanded up to 6 axes Learn more

Stepper Motor+Drive+Controller

AMCI by IDEC’s controller+drive+motor combo unit provides all-in-one motion control with all the features of the two-axis controller, drive and stepper motor. Learn more

Stepper Motor

AMCI by IDEC’s stepper motor comes in standard NEMA 23 frame sizes with output torque rating of 130 and 240 oz-in.

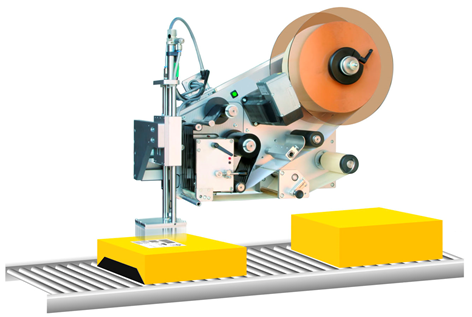

Application Examples

Advances in technology couple with customer demands brings about a push to combine one or more of the basic system components into one product.

Linear Applications

Flow Wrapper

Rotary Applications

Stepper Motion Controls

| Type | Part Number | Description |

|---|