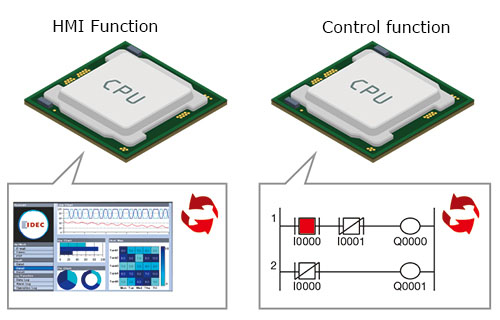

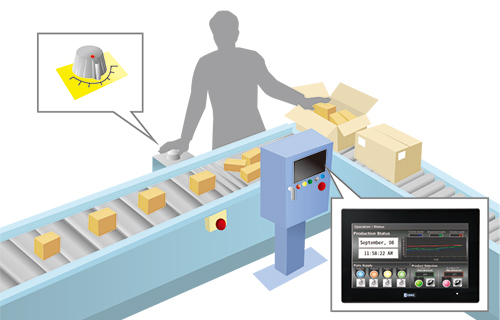

The FT1J and FT2J feature two CPUs working in parallel for the PLC and HMI. This design enables high-speed, real-time control without compromising HMI functionality, broadening the range of compatible applications.

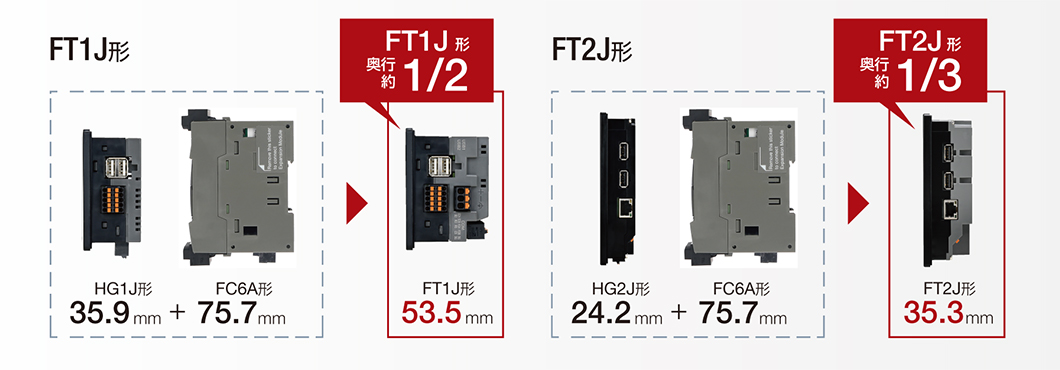

One PLC + HMI consumes less panel space than separate units. The FT1J requires only approx. half the depth of the two devices combined, and the FT2J requires approx. a third of the depth.

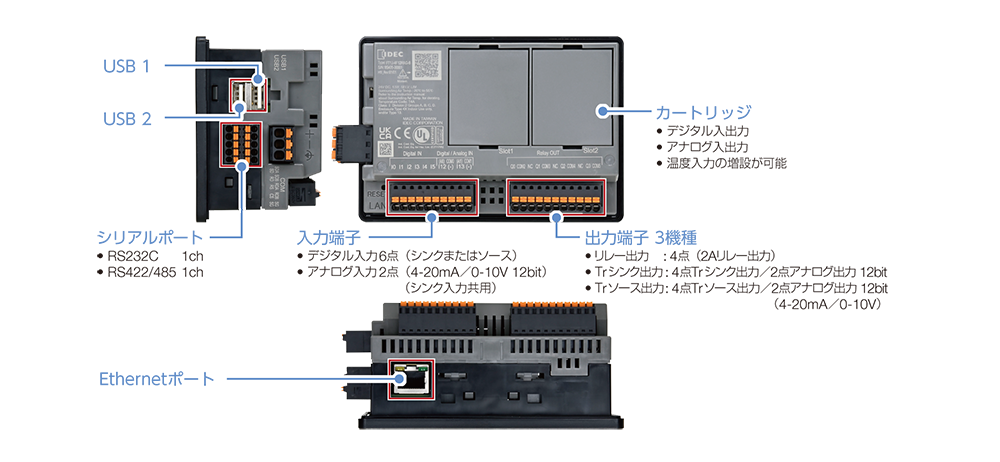

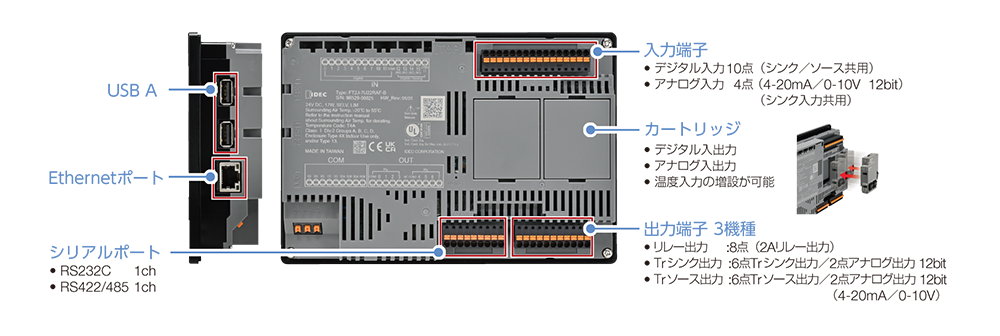

The detachable push-in terminal block improves wiring efficiency. It can be installed in tight spaces and enables easy wiring.

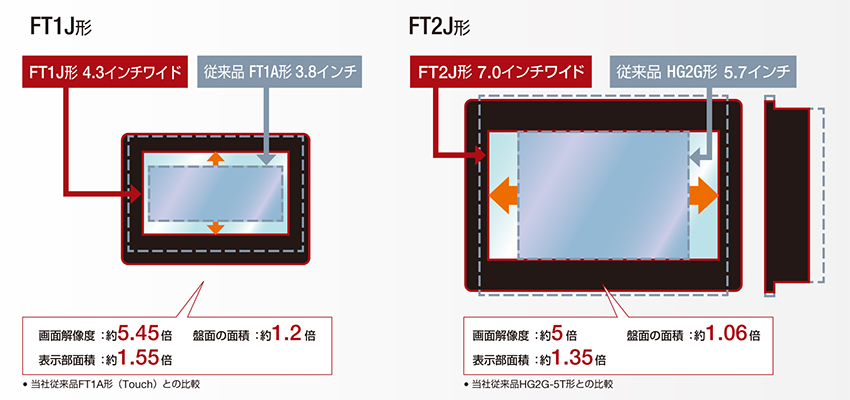

Significantly reduced slim bezel width enables the previous 3.8 inch and 5.7 inch displays to be replaced by larger and more immersive displays.

The operating temperature range for both devices is-20 to+55°C*. They can be used with equipment installed in hot and cold environments.

The glass PCAP touchscreen is very hygienic. It can be cleaned by spraying disinfectant or wiping with a wet cloth soaked in highly concentrated chemicals such as alcohol.

The surface of the FT1J and FT2J has a glass top structure that maintains high visibility and prevents deterioration and clouding from UV rays over a long period of time.

IP66F and IP67F ratings make these units suitable for cleaning with direct water jets.

The tempered glass maintains high impact resistance. The FT2J's panel (covered with protective film) passed a drop test with a 1kg steel ball (dropped onto the center of the glass from a height of 60cm). At a drop height of 80cm, even if the glass was damaged the protective film prevented glass shards from being scattered.1

1. The stated results are from in-house testing and do not guarantee performance.

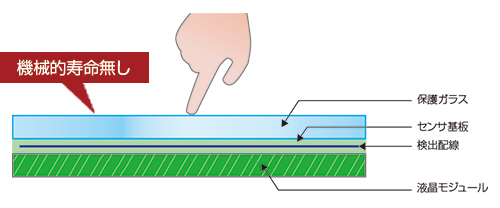

The PCAP touch panel uses a sensor board to detect changes in electric charge to identify the position of the touch. There is no mechanical deterioration, allowing for agile operation, and multi-touch sensing gloves less than 1.5mm thick2 can be used.

2. The touchscreen may not work with gloves less than 1.5mm thick depending on the material or environment. Check operation in the actual use environment or under similar conditions.

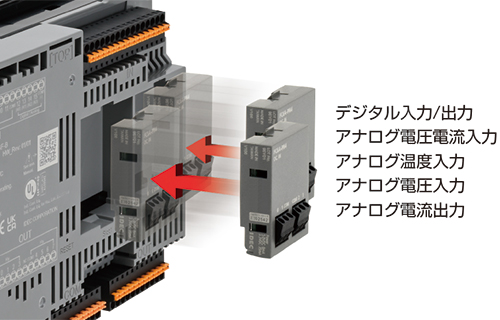

Up to 2 digital I/O cartridges or analog I/O cartridges can be connected, to add up to 8 digital I/O and up to 4 analog I/O.

Equipped with a built-in analog I/O to control analog signals from 0 to 10V DC (4 to 20 mA) with 12-bit resolution. An analog potentiometer connected to the analog input allows for easy configuration of analog settings, such as a timer.

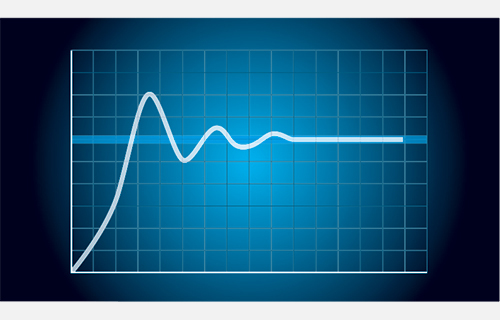

A PID algorithm is used to enable cascade control. Available for applications requiring temperature, flow, and pressure control.

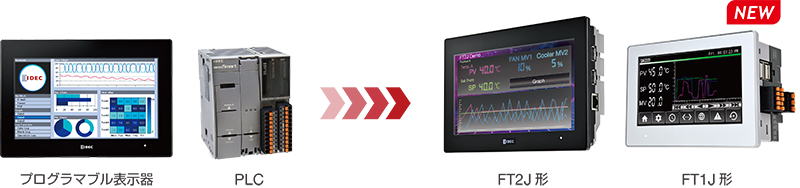

In cases where you want to use more I/O points than the FT1J/FT2J can offer, it is possible to upgrade to an operator interface and PLC configuration and reuse your software assets.