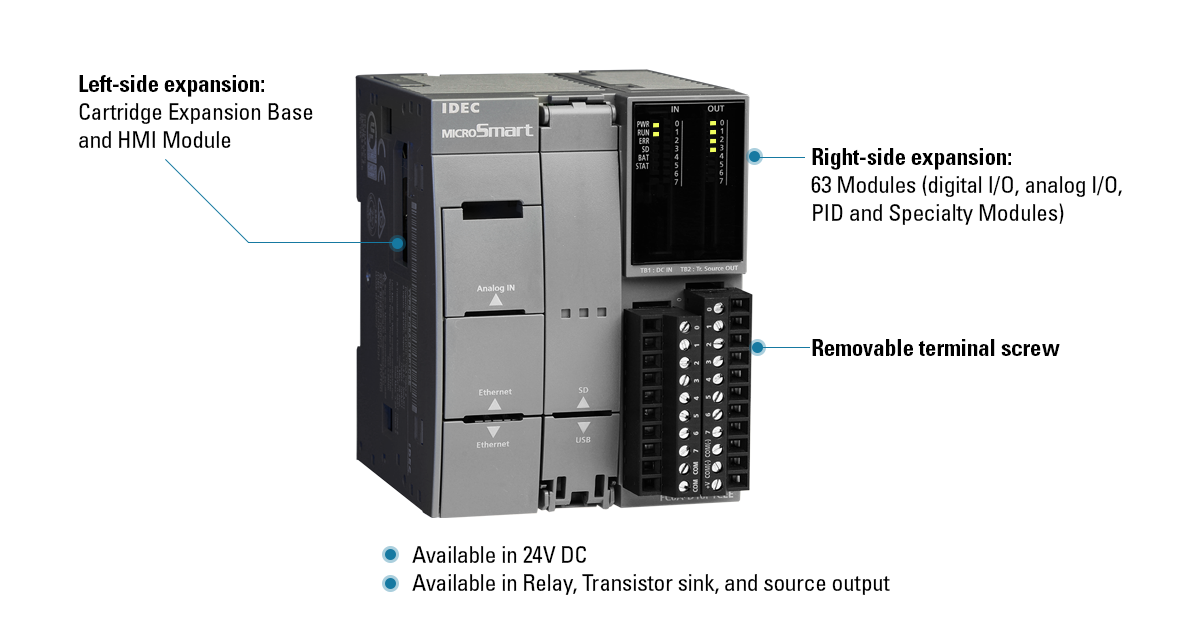

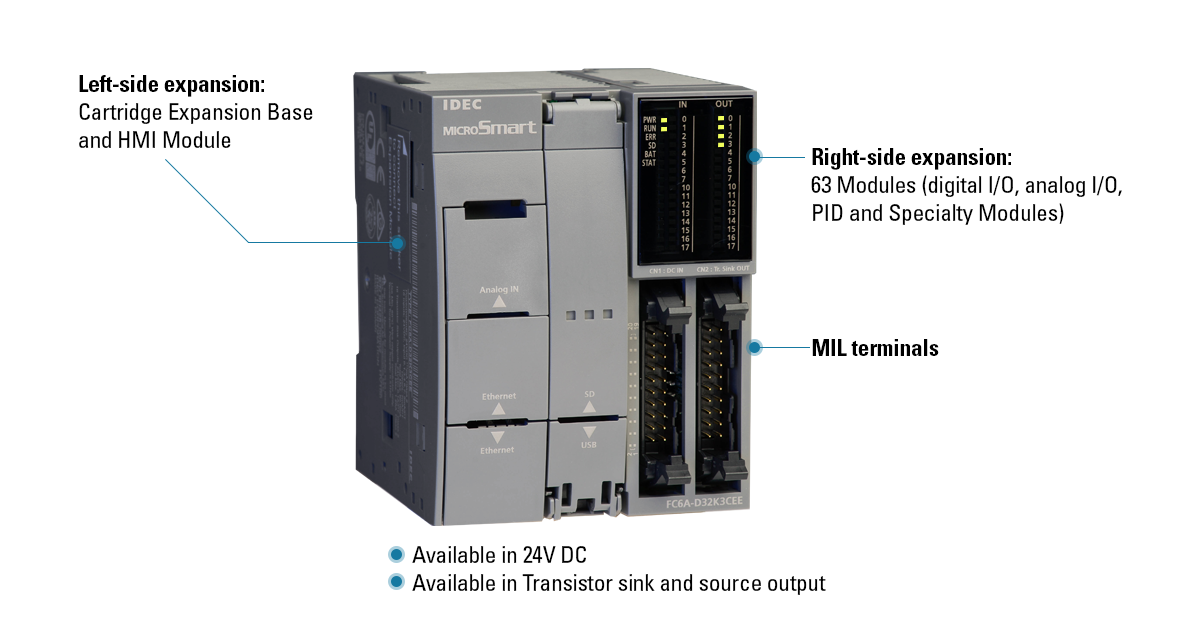

FC6A MicroSmart

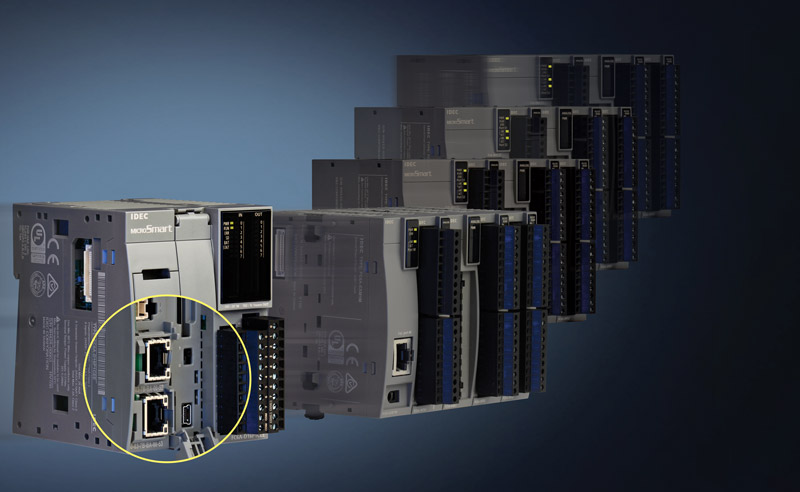

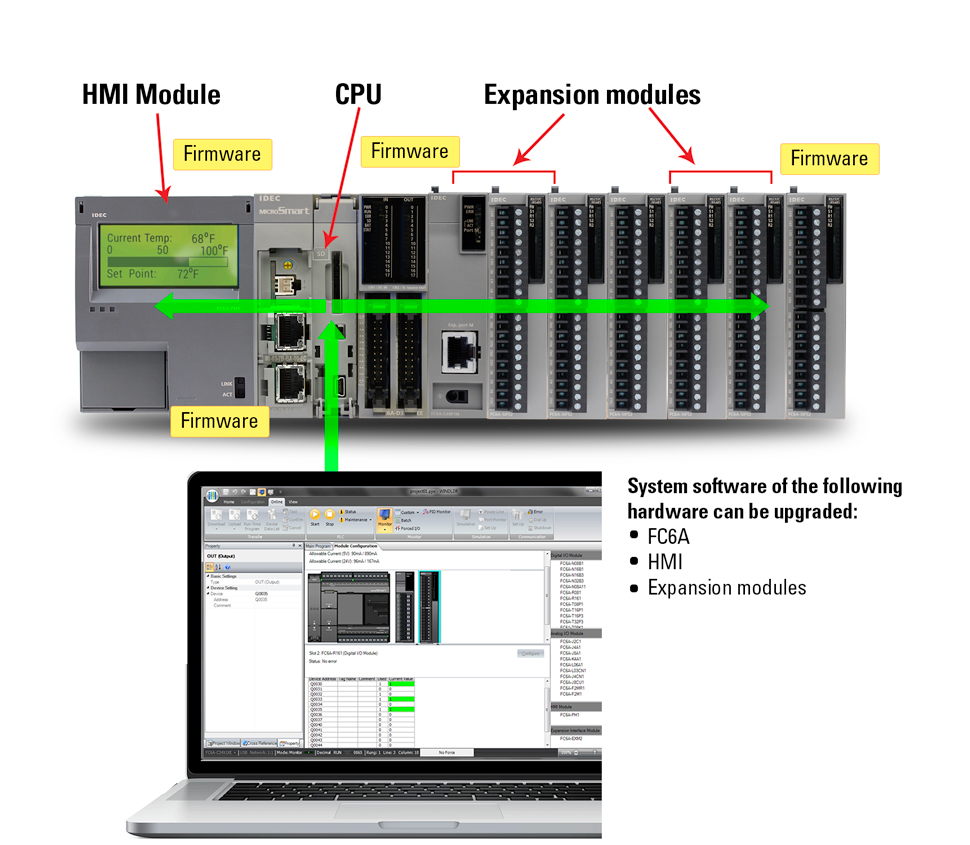

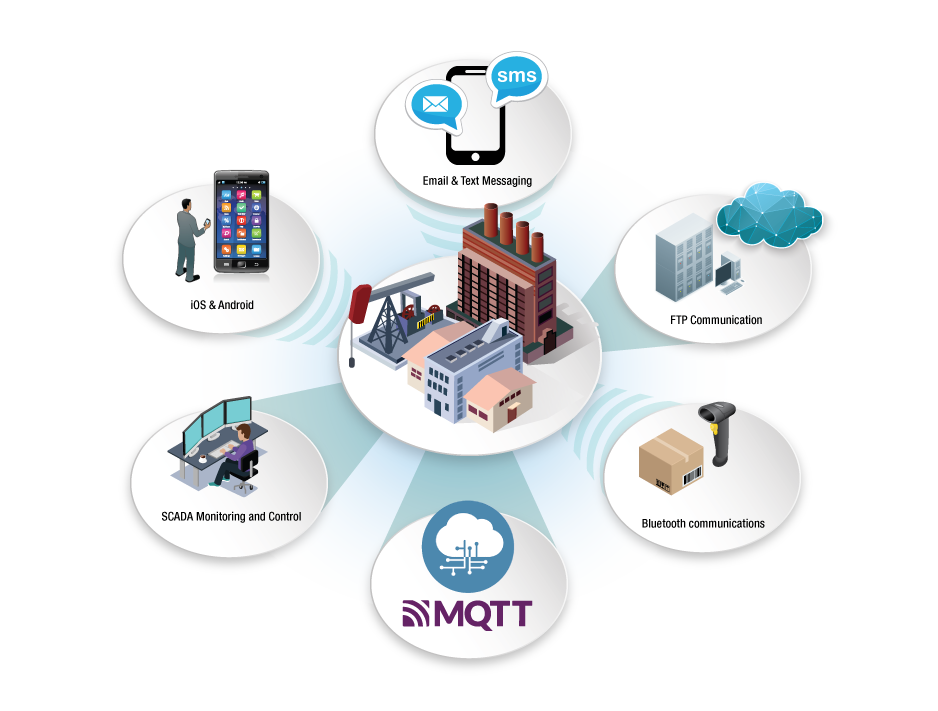

MicroSmart FC6A , a powerful PLC with up to 520 digital I/O and 126 analog I/O. The MicroSmart FC6A provides the power of a PAC (programmable automation controller) in a low-cost controller with a small form factor, making it an ideal fit for demanding applications. Learn more

Controller

A 2-axis motion controller that can be expanded up to 12 axes. It can accept encoder feedback to provides stall detection and move verification. It includes six discrete inputs for move conditioning and other functions, and four discrete outputs to indicate status and provide diagnostics. Learn more

Drive+Controller

AMCI by IDEC’s integrated Stepper controller+drive combo is a ground-breaking approach to PLC-based motion control systems. With its servo performance in a stepper motion hardware, the IANG1 series can be expanded up to 6 axes Learn more

Learn more

Stepper Motor+Drive+Controller

AMCI by IDEC’s controller+drive+motor combo unit provides all-in-one motion control with all the features of the two-axis controller, drive and stepper motor. Learn more

Stepper+Drive

AMCI by IDEC’s motor+drive combo unit can control one to six axes of motion, and it combines all the features of the two-axis controller and the drive into a single unit.. Learn more

Drive+Controller

AMCI by IDEC’s integrated Stepper controller+drive combo is a ground-breaking approach to PLC-based motion control systems. With its servo performance in a stepper motion hardware, the IANG1 series can be expanded up to 6 axes Learn more

Stepper Motor+Drive+Controller

AMCI by IDEC’s controller+drive+motor combo unit provides all-in-one motion control with all the features of the two-axis controller, drive and stepper motor. Learn more

Stepper Motor

AMCI by IDEC’s stepper motor comes in standard NEMA 23 frame sizes with output torque rating of 130 and 240 oz-in.

Many industrial applications require motion control, but users are often frustrated by the complexity and high cost of implementation. IDEC Corporation and AMCI, an established supplier of motion control systems, have partnered to address this issue by offering a simple yet highly capable stepper motion control system. This AMCI by IDEC product line includes controllers, stepper motors, a combo controller+drive, a combo drive+stepper motor, and the 3-in-1 controller+drive+stepper motor. When combined with an IDEC FC6A PLC and its embedded motion control software modules, these products allow users to quickly and simply implement single- and multi-axis motion control in a wide range of industries and applications.

Many industrial applications require motion control, but users are often frustrated by the complexity and high cost of implementation. IDEC Corporation and AMCI, an established supplier of motion control systems, have partnered to address this issue by offering a simple yet highly capable stepper motion control system. This AMCI by IDEC product line includes controllers, stepper motors, a combo controller+drive, a combo drive+stepper motor, and the 3-in-1 controller+drive+stepper motor. When combined with an IDEC FC6A PLC and its embedded motion control software modules, these products allow users to quickly and simply implement single- and multi-axis motion control in a wide range of industries and applications.